Club Lab: how does it work?

Welcome to Club Lab

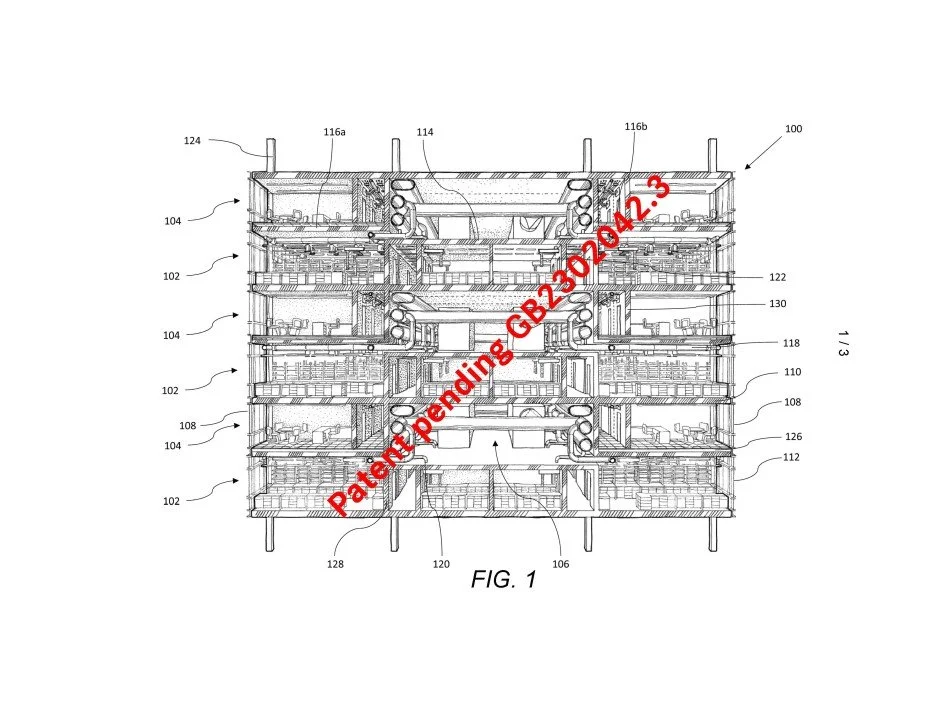

The quality and the efficiency of a lab building depends on how well the labs and the offices coexist within the structure. Using our patented methods of compacting mixed-used typologies, we developed an innovative way to combine lab, office and technical space. The result is a significantly more economical and flexible lab building. Club Lab is currently a patent-pending solution.

The Three Principles of Club Lab

Club Lab patent proposes three compositional principles leading to an exceptionally compact and flexible lab building. When used separately, the principles offer incremental optimization. Combined together, they yield a uniquely efficient, high-rise-capable lab building solution.

Principle One:

Alternating Lab and Office Floors

Lab buildings invariably contain office and meeting spaces. Labs require greater headroom for installations but do not feature raised floors. Offices necessitate raised floors for cabling but do not require as much headroom. In conventional lab buildings with offices located on the same floor as labs, approximately 20% of room height above the offices is wasted. Additionally, lab systems that serve only one portion of the floor are underutilized.

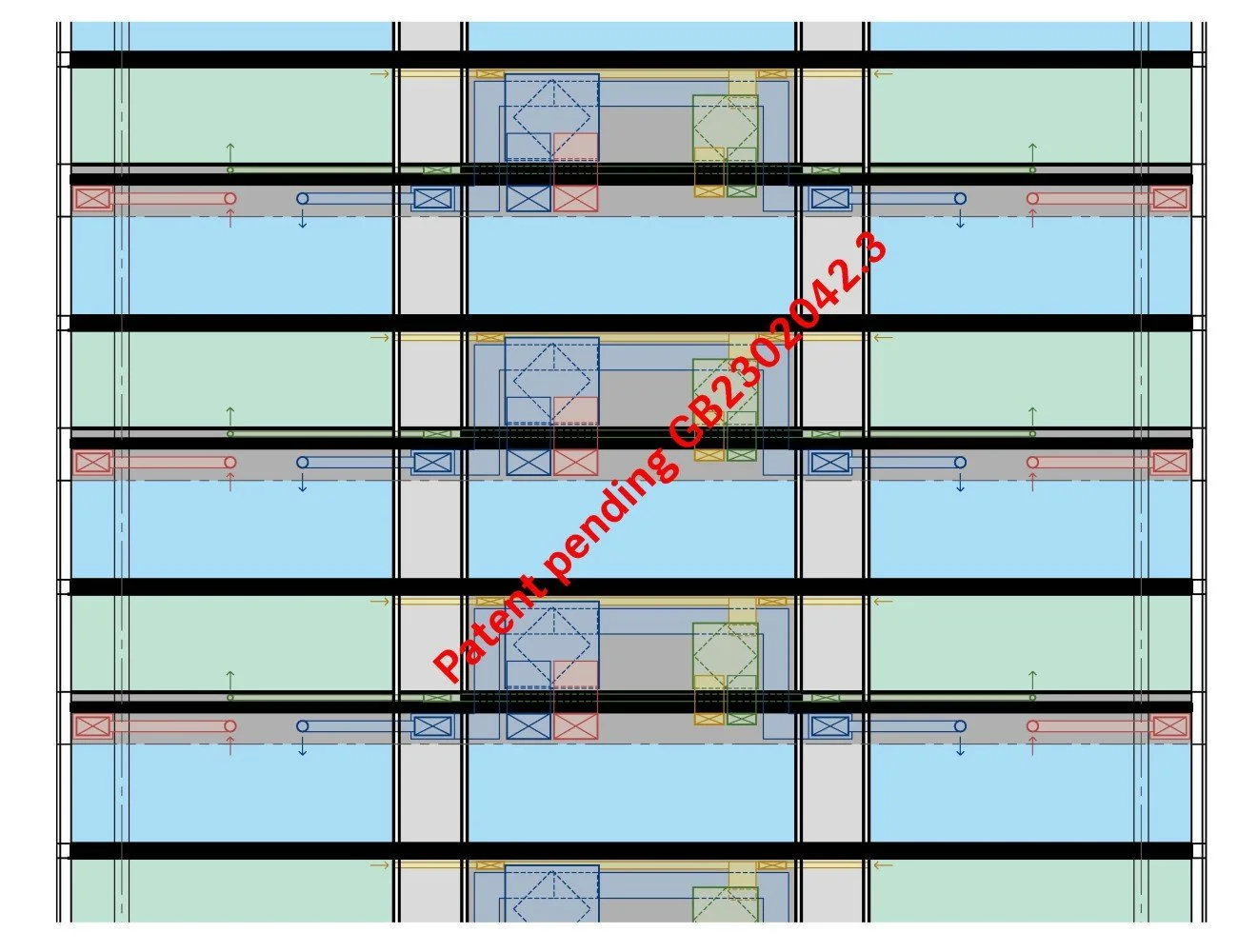

We address this dilemma by alternating the lab and office floors. Lab floors, featuring greater room heights and constructed with stronger slabs, offer ample systems installation space. Conversely, office floors, designed to be more economical, feature lower floor-to-floor heights and raised floors for efficient systems distribution.

Principle Two:

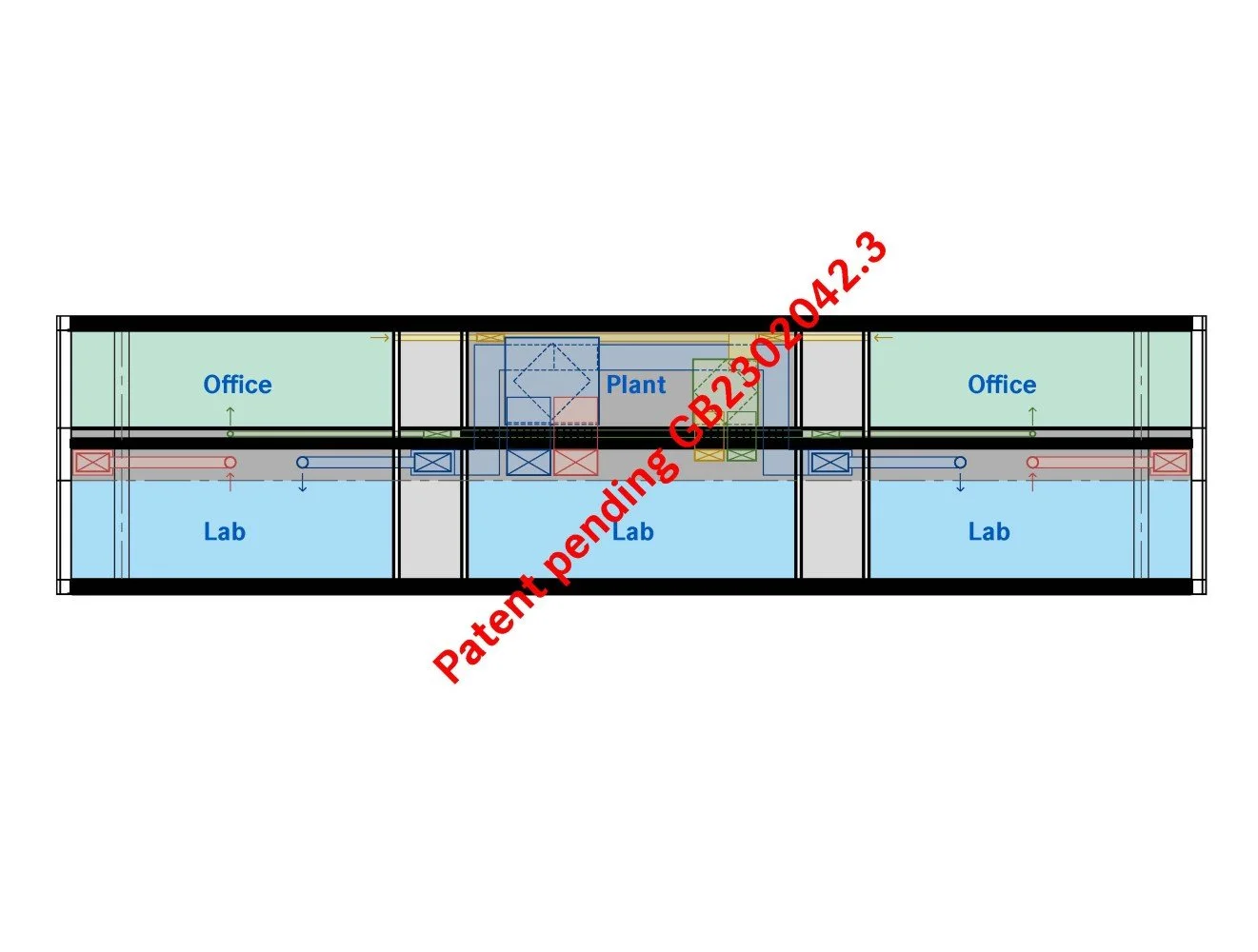

Distributed Mini-Plants

In conventional lab buildings, central plants necessitate dedicated technical floors, often located in expensive underground levels. We propose a more efficient approach: smaller, distributed mini-plants positioned in the middle of the office floors, each serving a single lab-office floor pair. These mini-plants are specifically sized to accommodate the equipment required for a particular lab-office floor pair. Our solution allows for the expansion of the plant room on a specific floor to accommodate additional equipment, for example, to increase air handling capacity or provide dehumidification or other air conditioning as needed. The distributed mini-plant scheme enables the creation of independent, on-demand custom-fitted ambient lab conditions on each lab floor. In the event of failures or during maintenance, only one floor is affected, while redundancy is ensured by a neighboring floor plant.

Principle Three:

Per-Floor Air Intake / The Disappearing Shaft

Smaller per-floor plants enable per-floor air intake for each lab-office floor combination. In this setup, only the extract air needs to be drawn through all the floors to the top of the building. In the absence of the air intake shafts, the shaft area requirement is reduced by half.

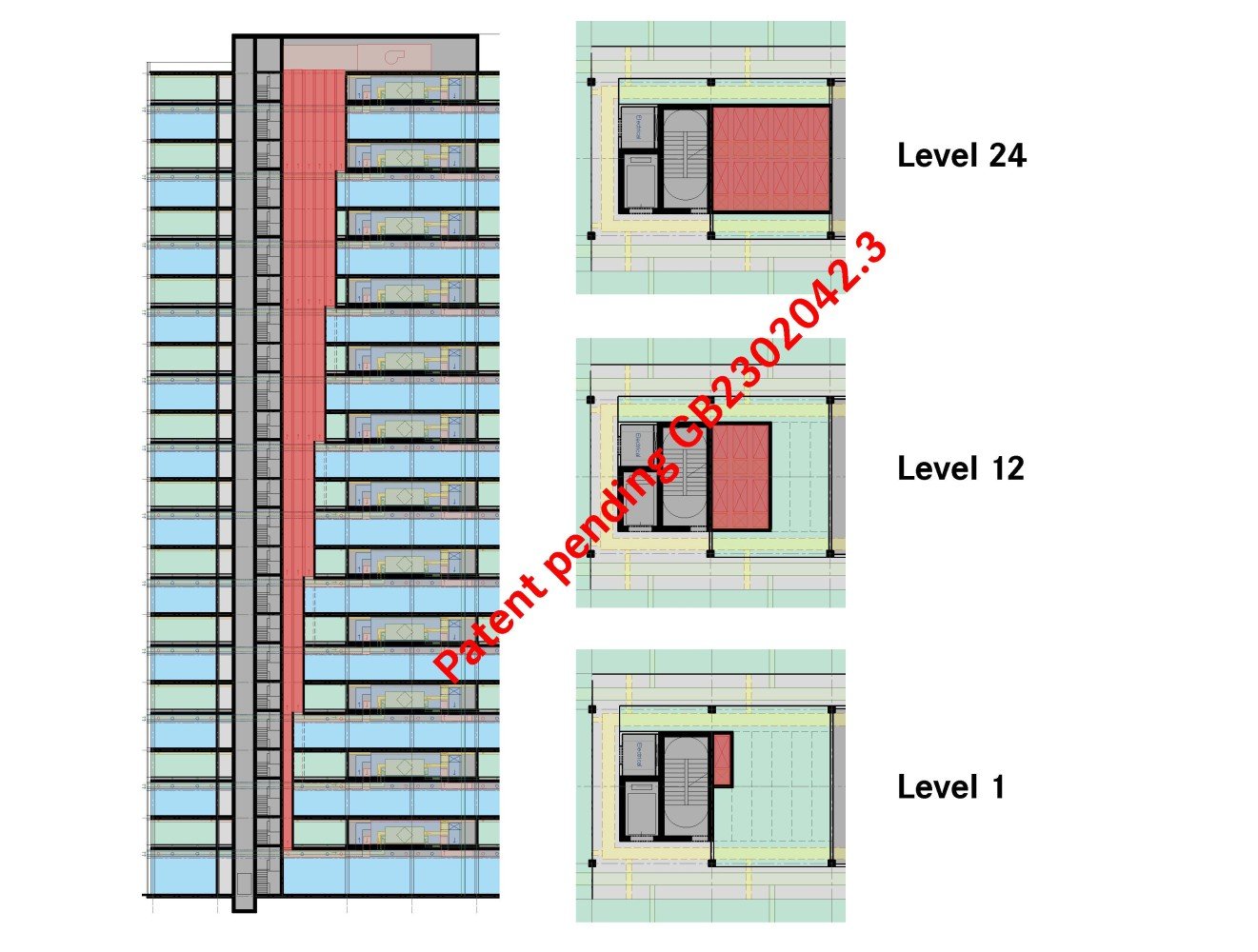

Going High-Rise

Club Lab was created with the idea of a high-rise lab building in mind. Conventional low-slung lab buildings in the suburbs will be challenged by more compact, taller clusters in high-density, high-value urban locations. Being able to work and live in a vibrant city is a bonus for today's researchers. Owners offering centrally located facilities will be winning in the global competition for the top research talent.

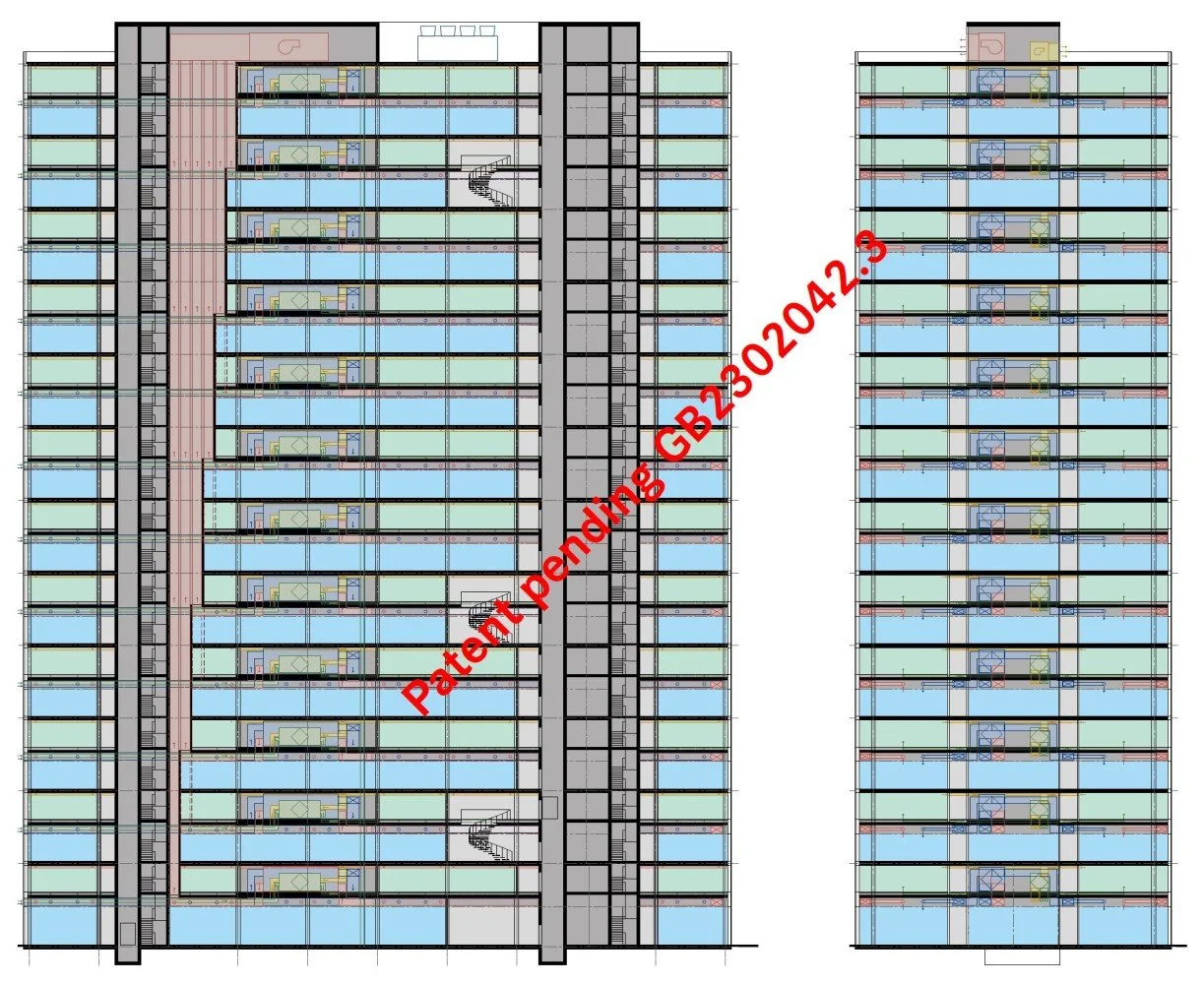

However, stacking more than six or seven lab floors presents technical challenges, requiring new high-rise lab solutions. Club Lab's autonomous Lab/Office two-story modules can be stacked to form a high-rise. Per-floor air intake resulting in radical reduction of the required shaft area allows to stack many floors without significant loss of useable floor area to shafts.

Here is a 24-story sample Club Lab building. Alternating lab and office floors are served by two stair and lift cores. Adjacent to the passenger lifts is an optional public stair connecting lab and office floors directly. Dedicated mini-plants each serving a lab/office floor sandwich are placed in the middle of office floors. Lab floors extend unobstructed from facade to facade. In the absence of air supply shafts, a stepping air extract shaft occupies only half of the otherwise required shaft space (hence the stepping). No expensive underground floors are needed to house a central plant replaced by the per-floor mini-plants.

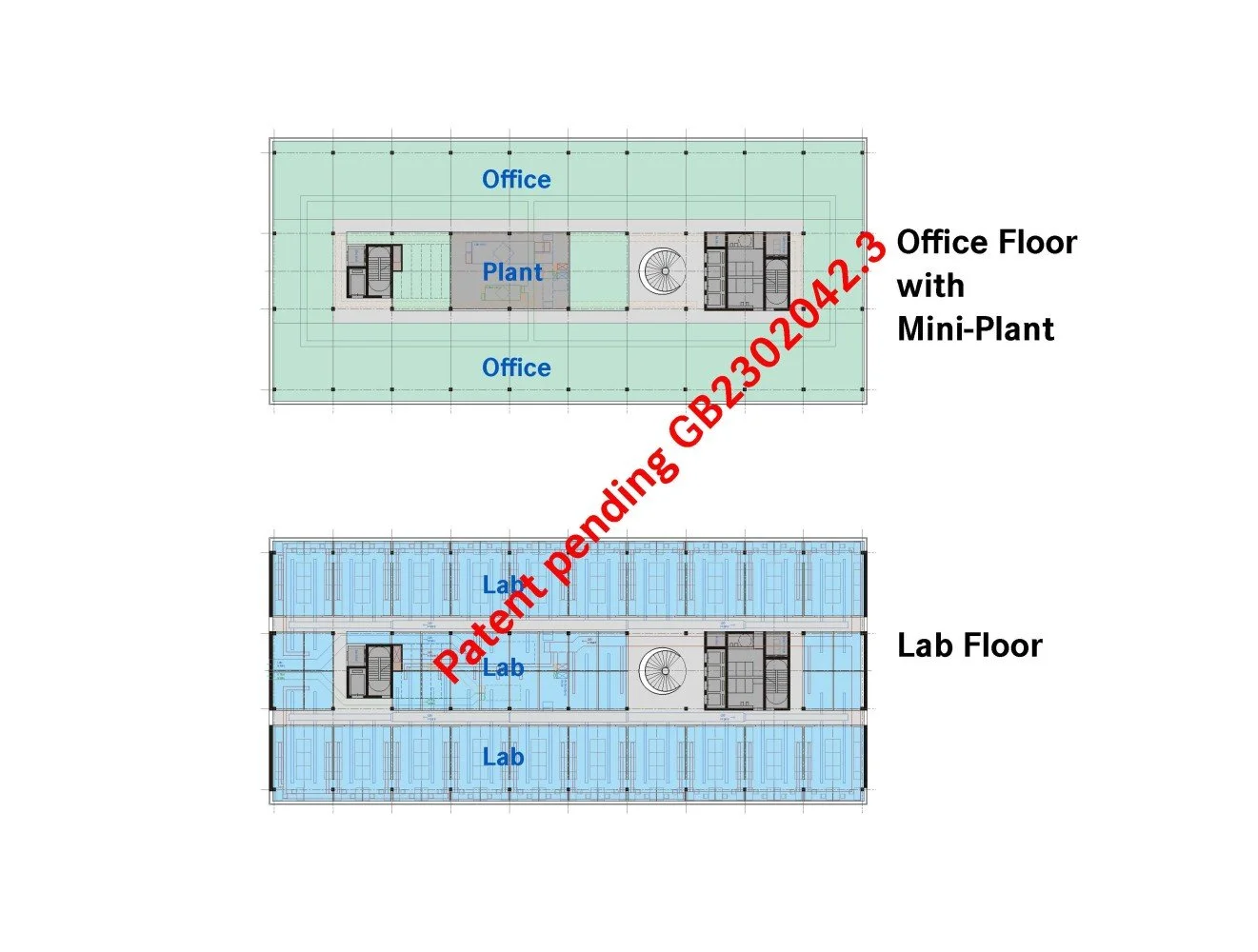

Club Lab floor plans

Each of the lab and office floors within the pair is fully dedicated to its respective function. The building is served by two cores. The "public" core, on the right, houses passenger lifts, toilets, and one egress stair, while an optional open communication stair connects lab and office floors. Collaborative and meeting areas on office floors are clustered around the public core. On the left, the "service" core contains the second egress stair, freight and chemicals lift, and the lab exhaust air shaft. This shaft is attached to the side of the core and expands in area on upper floors to accommodate increasing air volumes from the floors below. On the top floors, the shaft occupies the entire space between the service core and the plant room, which is located in the dark middle portion of each office floor.

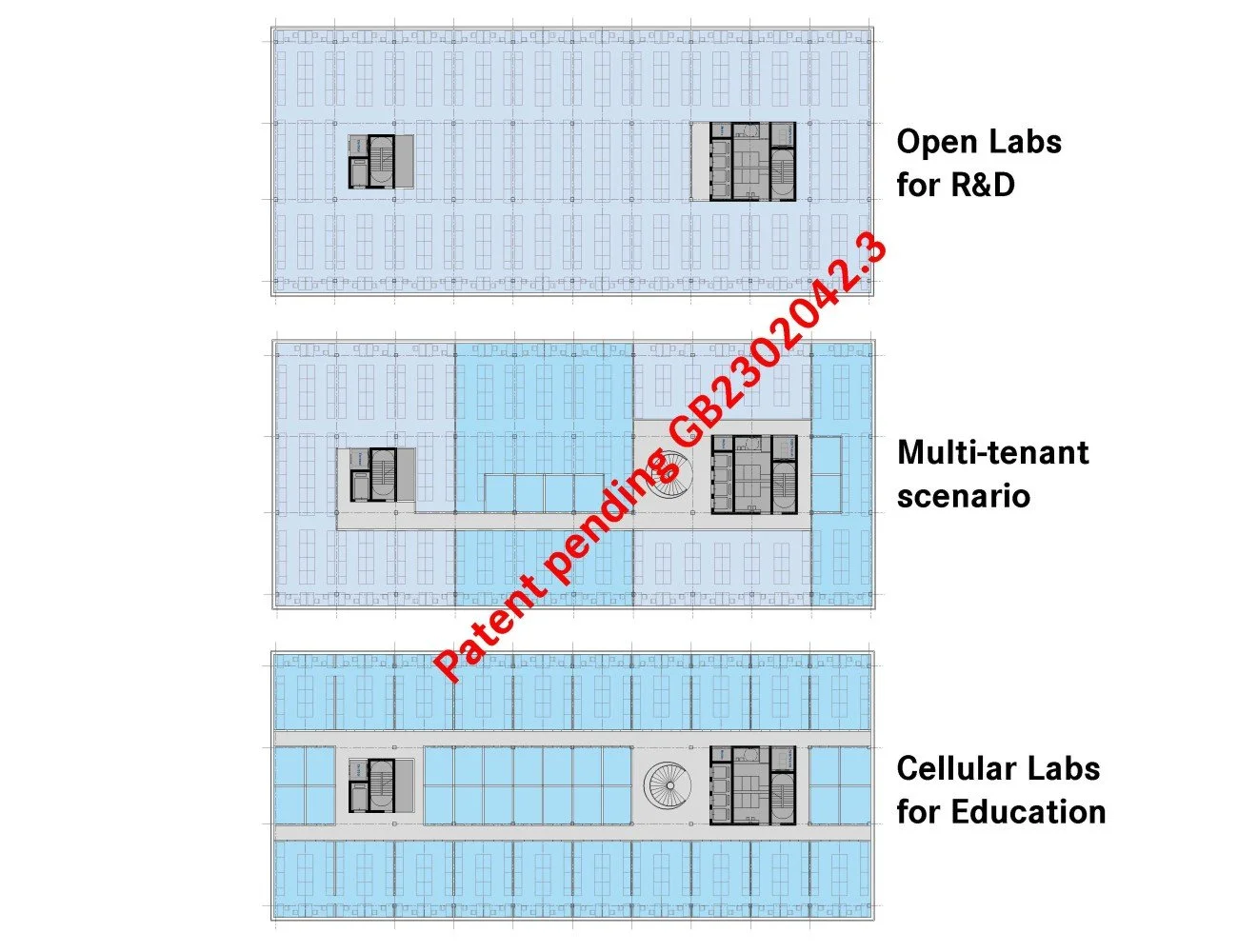

Lab floors can be fitted out with an open-space lab or cellular lab layout typical of educational labs or any combination thereof. In a commodity rental lab application the floor plate can be subdivided into multiple tenant lots. Mini-plants can be locally extended to accommodate tenant-specific optional equipment.

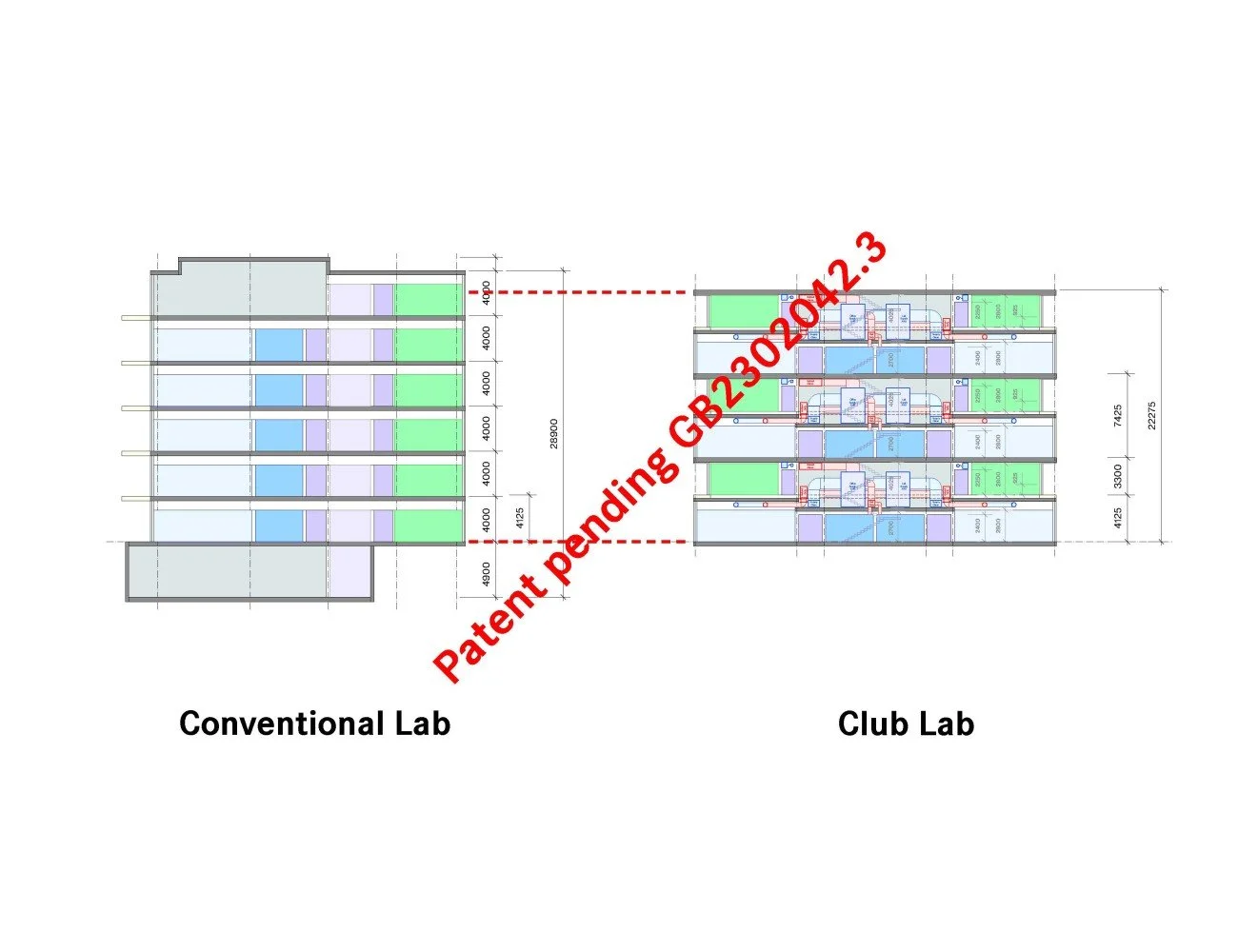

Benchmarking

When compared with a conventional lab building of similar size (on the left), Club Lab achieves remarkable efficiency by packing the same amount of lab and office space into a building that is 8% smaller in total area and 15% more compact in volume. These savings are further compounded with the height of the building. Club Lab requires less steel, concrete, and embedded CO2, resulting in a reduced construction time as well as reduced energy consumption in operation.

For a net usable area of 6,200m2, the conventional lab building (on the left) requires 11,000m2 of gross building area and 47,500m3 of building volume. Notably, the underground technical floor adds significant construction costs.

In contrast, the Club Lab-based building (on the right) achieves the same 6,200m2 of net usable area packed into just 10,500m2 of gross building area (an 8% savings) and 40,000m3 of building volume (a 15% savings). Club Lab eliminates the need for underground plant rooms. Additionally, each lab-office floor combination saves 0.5 to 1.0m of building height. About six Club Lab floors save enough building height for an additional floor.